Solutions for leakage problems encountered by Isuzu trash compactor truck

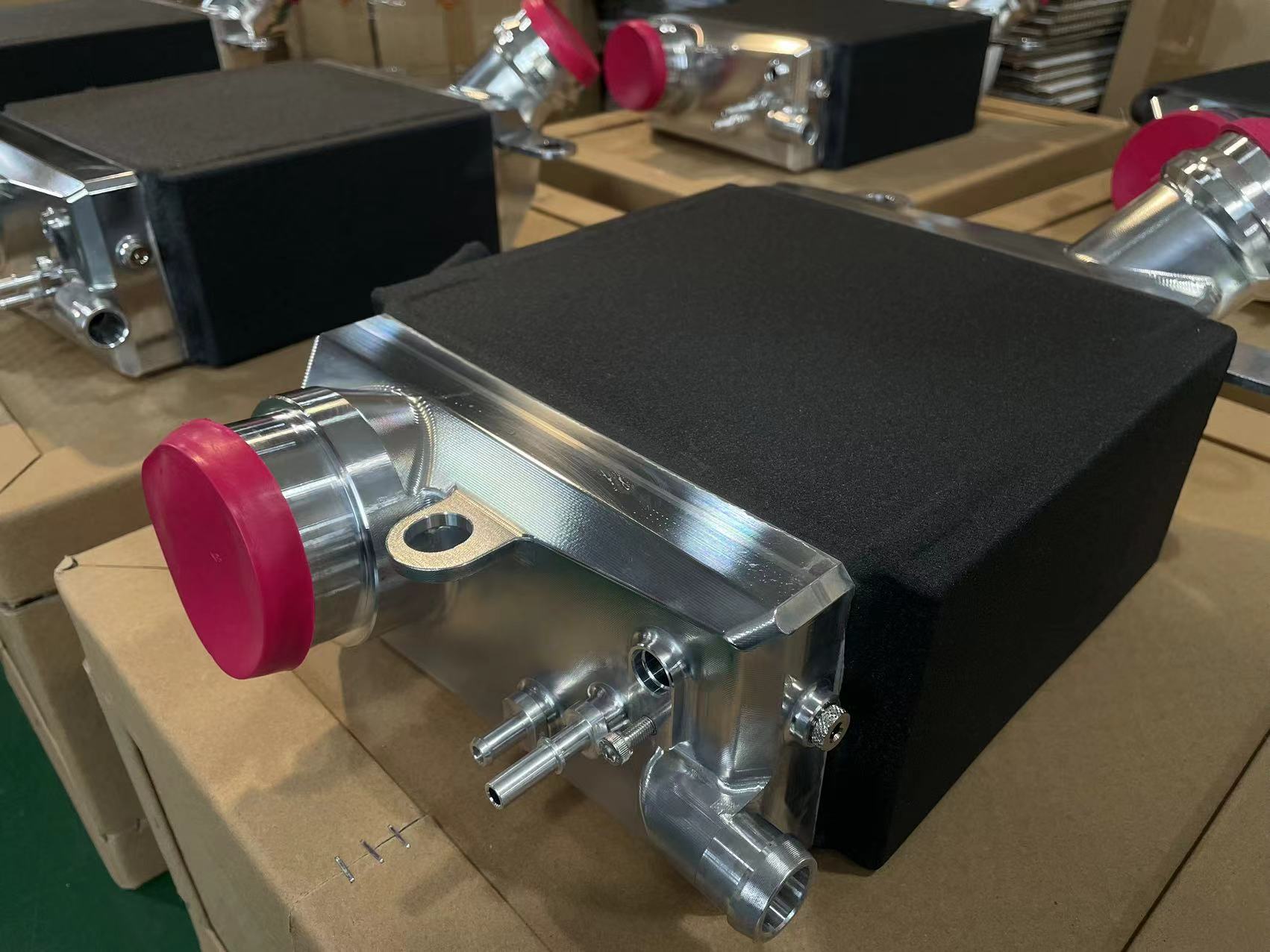

Isuzu rear loading compactor truck is an essential piece of equipment in urban sanitation work. By compressing garbage into small pieces and storing them inside the car body, it reduces the space occupied by garbage and improves collection and transportation efficiency. However, when using isuzutruckscn rear-loading compressed garbage trucks, leakage problems often occur inside the vehicle. If not dealt with in time, it will lead to environmental pollution and traffic safety hazards.

There are many reasons for the leakage problem of Isuzu garbage collector truck, such as poor body sealing, aging oil seal, damaged pipelines, cylinder wear, etc. For different reasons, we need to take corresponding measures. Below I will introduce to you how to deal with the leakage problem of rear-loading compressed garbage trucks.

First, we need to check the sealing performance of the Isuzu trash compactor truck body. If the car body seal is not good, it will cause garbage to leak out. Therefore, we should check whether the door seal is intact and whether it is deformed or aged. If the sealing strip is damaged, it should be replaced in time. If the sealing strip is only deformed, it can be restored after soaking in hot water. In addition, other sealing parts should also be checked, such as side seals and rear side panel seals.

Secondly, the aging oil seal of Isuzu trash compactor truck needs to be inspected and replaced. During the garbage compression process, the compression cylinder will move to both sides. If the oil seal is aged or damaged, hydraulic oil will leak out. Therefore, we should regularly check the status of the oil seals and replace aging or damaged oil seals in a timely manner. When replacing the oil seal, you should choose an oil seal with reliable quality, wear resistance and pressure resistance, and install it according to the corresponding installation requirements.

Third, we need to repair the broken pipes. When repairing hydraulic pipelines, appropriate connection methods and materials should be selected to ensure the sealing performance of the pipelines.

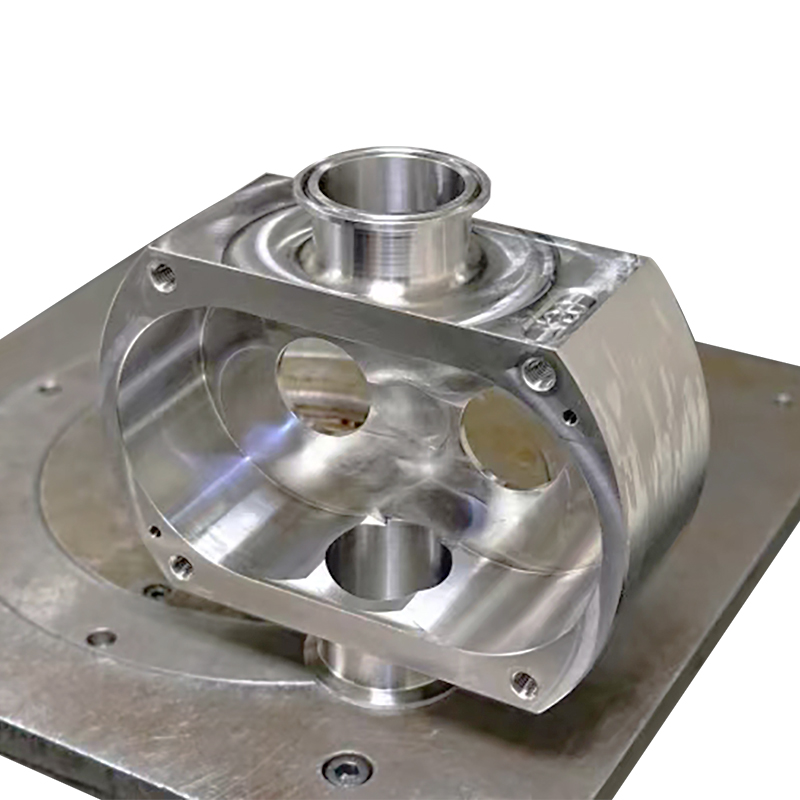

Fourth, if the Isuzu trash compactor truck cylinder is severely worn, the worn cylinder needs to be replaced. The compression cylinder of ISUZU dumpster compactor truck is compressed through a hydraulic cylinder. If the cylinder body is severely worn, it will affect the sealing performance of the hydraulic cylinder and lead to hydraulic oil leakage. Therefore, we should regularly check the status of the compression barrel and hydraulic cylinder, and replace seriously worn parts in a timely manner.

Fifth, the garbage truck needs to be cleaned. Especially the slag collection parts of garbage bins and garbage trucks should be thoroughly cleaned. This ensures that there is no residual garbage or liquid inside the garbage truck, reducing the possibility of leakage.

Finally, we need to perform regular maintenance on the garbage truck. Including checking and replacing seals, cleaning pipelines, overhauling hydraulic systems, etc. Through regular maintenance and upkeep, the normal operation of the garbage truck can be ensured and the occurrence of leakage problems can be reduced.

To sum up, dealing with the leakage problem of Isuzu trash compactor truck requires targeted measures. We need to choose the appropriate treatment method according to the specific problem. In daily use, vehicles should be inspected and maintained regularly to avoid leakage problems in garbage trucks. This can better protect the environment and ensure traffic safety.